"To achieve sustainability, we must not only measure emissions but understand the entire value chain and work together for meaningful change."

As businesses face increasing pressure to address climate change, measuring and managing Scope 3 emissions has become a critical component of a company’s sustainability efforts. But what exactly are Scope 3 emissions, and why do they matter? In this post, we’ll explore the significance of Scope 3 emissions, why they are often the largest part of a company’s carbon footprint, and why adopting a supplier-specific method for calculating these emissions is the most accurate and effective approach.

What Are Scope 3 Emissions?

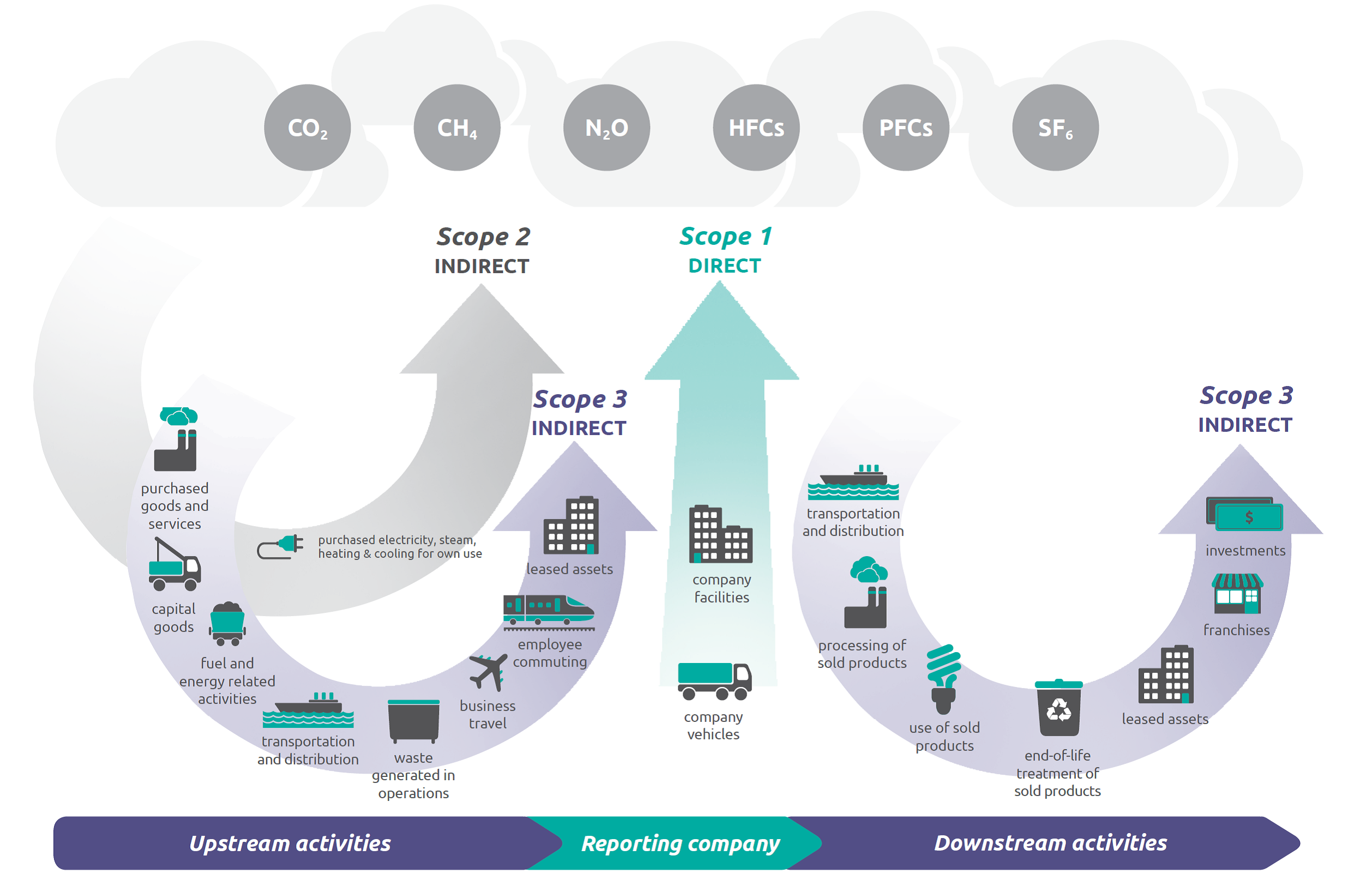

Scope 3 emissions are the indirect greenhouse gas (GHG) emissions that occur throughout a company’s value chain, including both upstream (before the product reaches the company) and downstream (after the product leaves the company) activities. Unlike Scope 1 emissions (direct emissions from owned or controlled sources) and Scope 2 emissions (indirect emissions from purchased electricity), Scope 3 covers a broad spectrum of activities that often lie outside the company's direct control.

These emissions can come from a variety of sources, such as:

- Upstream emissions: This includes emissions from the production of purchased goods, business travel, employee commuting, and transportation of raw materials.

- Downstream emissions: This includes emissions from the use of sold products, end-of-life treatment, and emissions from franchises and investments.

Scope 3 emissions are often the hardest to measure accurately, yet they represent a substantial portion of a company’s total carbon footprint. For some companies, Scope 3 can account for up to 80% of total emissions, which makes tracking and reducing them critical for achieving sustainability goals.

Why Is It Crucial to Measure Scope 3 Emissions?

Understanding Scope 3 emissions is essential for several reasons:

1. A Holistic View of Carbon Footprint

When companies ignore Scope 3 emissions, they miss a significant part of their environmental impact. By accounting for all emissions, including those from suppliers and the end use of products, businesses get a comprehensive view of their carbon footprint. This is essential for setting realistic and achievable sustainability goals.

2. Compliance with Regulations and Standards

Increasingly, governments and regulatory bodies are requiring businesses to disclose their emissions, including Scope 3. Global frameworks such as the Greenhouse Gas Protocol (GHG) and CDP are encouraging companies to report on all emissions across their value chain. For companies aiming to meet regulatory requirements or attract investment, measuring Scope 3 emissions is not optional—it’s a necessity.

3. Mitigating Risk and Enhancing Reputation

Companies that fail to account for Scope 3 emissions risk facing reputational damage, stricter regulations, and supply chain disruptions. Understanding where emissions are coming from allows businesses to identify risks related to resource scarcity, changing regulations, or shifting consumer expectations. Additionally, companies that show a commitment to reducing their carbon footprint can strengthen their brand’s reputation and appeal to more environmentally-conscious customers and investors.

Approaches to Measuring Scope 3 Emissions

To calculate Scope 3 emissions, companies typically rely on a few different methods. Each has its strengths and weaknesses, but the supplier-specific method has become the gold standard for several key reasons.

1. The Spend-Based Approach

This method uses the financial expenditure data to estimate emissions, calculating the emissions per dollar spent on purchased goods and services. This approach relies on average emissions factors, making it quick and easy to use.

Pros: Simple and cost-effective, using financial data that companies already track.

Cons: It’s an approximation and doesn’t account for variations in supplier practices or specific activities that might have a higher or lower emissions impact.

2. The Activity-Based Method

With this approach, companies calculate emissions based on specific physical activities such as the distance traveled by freight or the weight of goods produced. Emission factors are then applied to these activities.

Pros: More accurate than the spend-based method, particularly when detailed data on activities is available.

Cons: Requires more granular data, which may not always be easy to obtain, especially if a company is sourcing from multiple suppliers or has complex supply chains.

3. The Supplier-Specific Method

The supplier-specific method involves directly engaging with suppliers to obtain real-world emissions data from their operations. By tracking emissions for each specific supplier, this method offers a much more detailed and precise picture of a company’s Scope 3 emissions.

Pros: Highly accurate as it reflects the specific emissions data from suppliers. It provides actionable insights into the emissions associated with each supplier’s processes and products.

Cons: Time-consuming and resource-intensive, as it requires strong supplier relationships and data collection.

Why Opt for the Supplier-Specific Method?

While the spend-based and activity-based methods have their uses, the supplier-specific method is by far the most accurate and comprehensive. Here’s why:

1. Precision in Measurement

The supplier-specific method delivers more precise data because it directly reflects the emissions associated with each supplier’s unique practices. For example, two suppliers might produce the same type of product, but one could have a much lower carbon footprint due to advanced technology or sustainable practices. Using a supplier-specific method ensures these differences are captured, rather than relying on average data.

Example: If one supplier reduces emissions by adopting renewable energy or optimizing their production process, the supplier-specific method will capture these changes, providing a more accurate account of emissions.

2. Building Stronger Supplier Relationships

Engaging suppliers in the emissions measurement process helps businesses form stronger partnerships. By collaborating with suppliers to track and reduce emissions, companies can identify areas for improvement in their supply chain and work together to implement more sustainable practices.

Example: A company might identify that a supplier’s emissions are high due to inefficiencies in production. By working together, they can develop solutions, like switching to renewable energy or investing in more energy-efficient machinery.

3. Improving Transparency and Credibility

Using supplier-specific data enhances transparency and credibility in emissions reporting. Stakeholders, including investors, customers, and regulatory bodies, prefer precise, supplier-specific emissions data over generalized estimates. When companies disclose the actual emissions data from their suppliers, it boosts their credibility and positions them as leaders in sustainability.

Example: If a company reports emissions data based on broad industry averages, stakeholders might question the accuracy of the data. However, detailed data from suppliers provides a clearer and more trustworthy report.

4. Uncovering Opportunities for Emission Reductions

One of the biggest advantages of the supplier-specific approach is its ability to highlight opportunities for emission reductions. By having detailed emissions data, businesses can identify areas of the supply chain that have the highest emissions and focus on these areas for improvements.

Example: A tech company working with several suppliers for electronic components might discover that one supplier is significantly less efficient in its operations. By collaborating with this supplier to improve their processes, the company can reduce overall emissions and contribute to a more sustainable supply chain.

Conclusion

As businesses strive to meet ambitious sustainability goals, Scope 3 emissions play a critical role in shaping their overall carbon footprint. While calculating Scope 3 emissions can be challenging, using the supplier-specific method offers the most precise, transparent, and actionable insights into a company’s environmental impact. It may be more time-consuming, but the accuracy it provides—and the potential improvements it can unlock across the supply chain—are well worth the effort.

By embracing this method, companies can not only reduce their emissions but also improve relationships with suppliers, boost their credibility with stakeholders, and position themselves as leaders in the fight against climate change. The future of sustainable business practices is built on collaboration, and the supplier-specific method is the key to making that future a reality.